According to a report released by IHS Markit yesterday, the semiconductor shortage in the automotive industry is expected to continue until the second quarter of 2022, and will result in a reduction in global vehicle production by 6.3 million to 7.1 million in 2021.

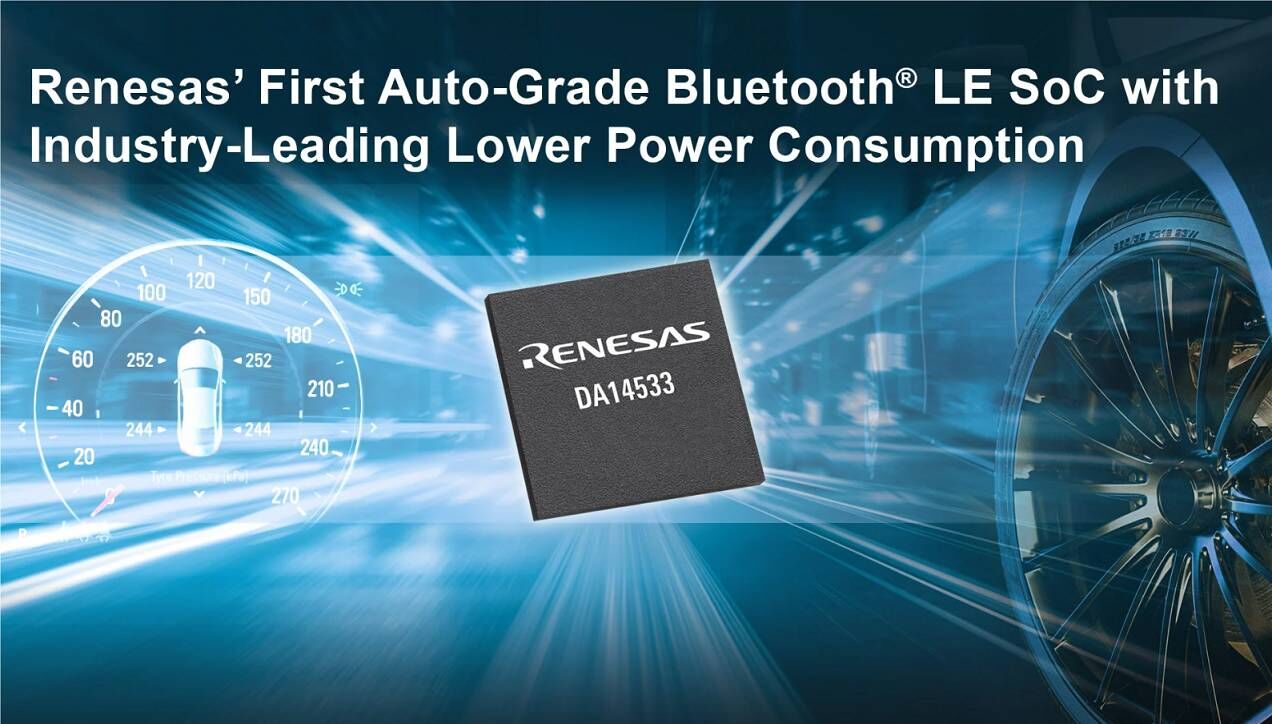

The report pointed out that in the first half of 2021, the main reason for the semiconductor shortage was wafer production capacity. As the Renesas fab resumed production after the fire, and other chip fabs closed due to the Texas winter storm began to resume operations, the situation began to improve. However, in the second half of the year, wafer capacity is no longer the only reason for chip shortages.

"Wafer fab capacity got all the attention early this year, and rightly so, but if you can't put the die into a package so it can be put into an ECU, then you still can't produce and sell a car," said Phil Amsrud, senior principal analyst at IHS Markit.

At the same time, the supply chain disruption caused by the epidemic is also increasing. The epidemic threatens operators at semiconductor packaging and testing sites, as well as the workers needed to ship finished products to global distribution centers. In addition, semiconductor packaging and testing capacity limitations affect all types of semiconductors, including sensors, power ICs, and discrete devices.

To solve the shortage, semiconductor packaging and testing providers need to expand their production capacity like fabs. However, due to low profits, packaging factories are cautious in increasing production capacity. In addition, the lead time of some packaging equipment has increased to 40 weeks due to chip shortages.

The report pointed out that the loss of vehicle production caused by the interruption of the semiconductor supply chain is expected to reach 1.44 million units in the first quarter and 2.6 million units in the second quarter. If the shutdown continues until September, it will reach 1.8 million to 2.1 million units in the third quarter. For the whole year, the number of reductions in vehicle production caused by the global semiconductor shortage will range from 6.3 million to 7.1 million.

In summary, IHS Markit predicts that the semiconductor shortage in the entire automotive industry will continue into the first quarter of 2022 and may continue into the second quarter, and the recovery will not begin until at least the second half of 2022.

All Comments (0)