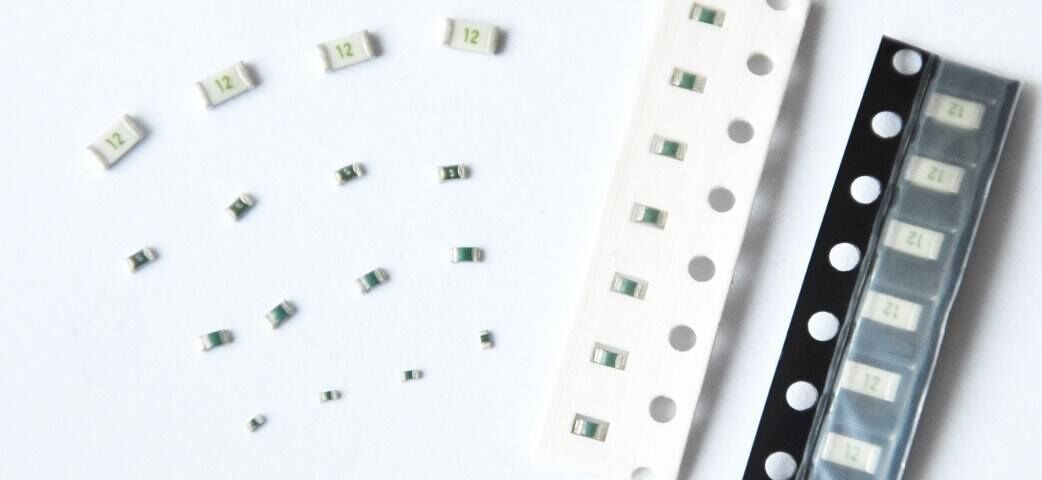

On May 22nd and 24th, the resistor producers RALEC and Uniohm issued notices of price increases respectively. The reasons for the increase were all due to the increase in the price of raw materials, and the effective date of the new price was also June 1st.

Judging from the current situation, the situation of increasing prices for resistor shortage still intensifying. This is the third time that RALEC and Uniohm have adjusted their prices this year. RALEC raised some of its chip resistors by 15% in January this year. In March, some thick film resistors price were increased by 25%; Uniohm increased the chip resistors of 0402~2512 size and all sizes of Array chip-resistor by 15-20% in January this year, and increased again the chip resistors of 0402-2512 size and all Array chips by 25~30% in March.

According to industry sources, consumer electronics and other market demands continue to increase, resulting in tighter resistor capacity supply, coupled with China's environmental protection requirements and other factors, causing a serious shortage today.

In response to market demand and the China's environmental protection policy, RALEC has expanded its production capacity while transferring production sites from last year. The monthly capacity of the RALEC Kunshan plant is approximately 14 billion units, and the Malaysian plant is approximately 11 billion units. In the case of Kunshan government's environmental protection requirements to limit production, the company has already transferred 50% of the previous process to Malaysia. The remaining 50% may be transferred to Hunan, China this year. The company will also expand its production in Malaysia. The Hunan factory is also expected to increase its monthly production capacity by 2 billion units in the third quarter of this year. The total production capacity will reach 35 billion.

At present, the situation of resistor manufacturers receiving orders is indeed very tight, and the product supply gap has spread from general-type resistors to high-precision resistors, and the lead time has become longer. Some manufacturers have already added new production capacity to meet demand. The shortage of the resistance market coupled with environmental protection policies to limit production, raw materials, and other conditions, the price is showing a trend of skyrocketing.

The resistor makers stated in the price increase notification that the reasons were rising raw material prices, excessive demand for production capacity, and strengthened environmental protection. In fact, these price increases do have a tendency to follow suit. After all, this is a bull market in which passive electronic components are rarely seen for decades, most manufacturers hope that they can make some profits during this period. However, the balance between supply and demand is fundamental. At present, the resistor manufacturers have been actively expanding production, we believe that the supply of resistor will keep tight until Q4 of 2018.

All Comments (0)