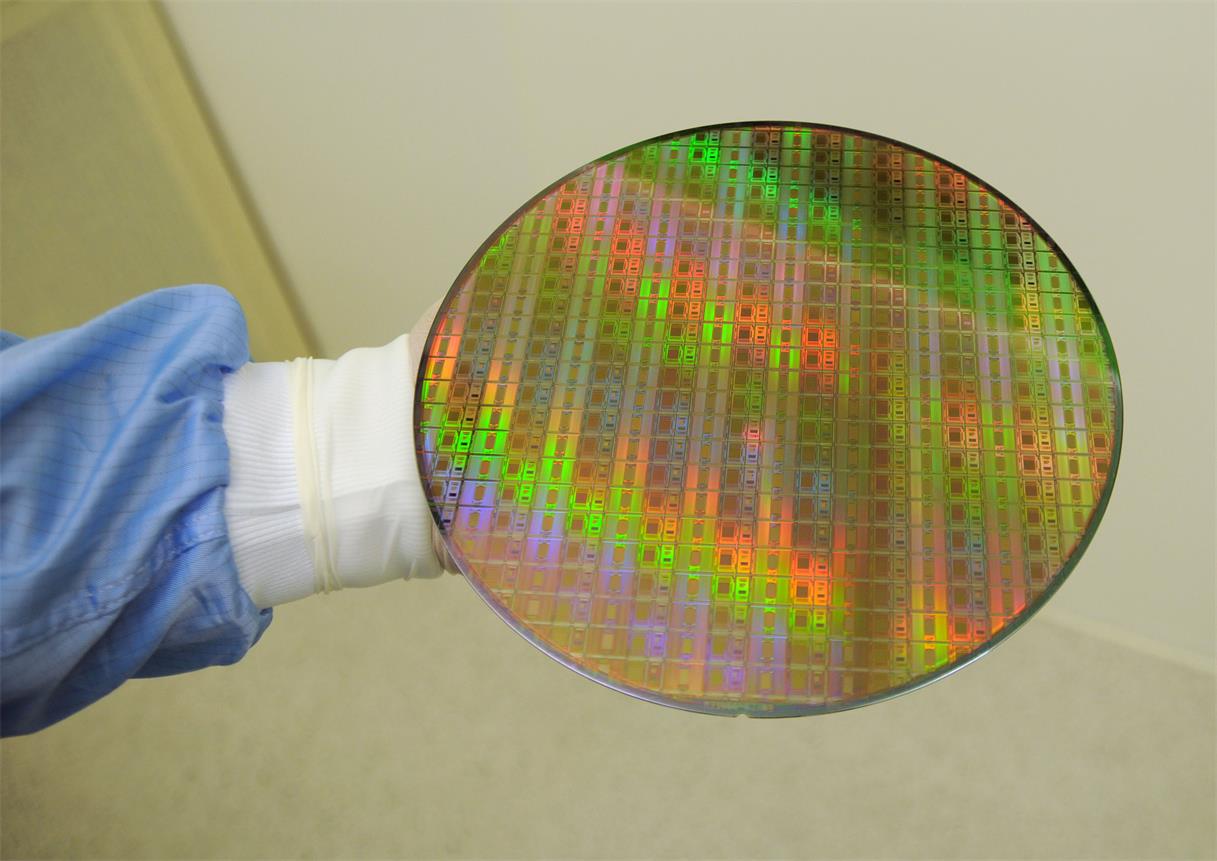

UMC, a Taiwan-based semiconductor wafer foundry, recently stated that due to the shortage of 8-inch wafer foundry capacity, the price has recently risen formally, and the expansion of its 8-inch wafer foundry in mainland China has started, it is the largest expansion in the past three years. The industry revealed that UMC's price increase rate may be as high as 20%, which is unprecedented, coupled with the large-scale expansion, it seems that UMC is very optimistic about the future market trends.

UMC held a shareholders meeting yesterday (12). CFO Liu Qidong confirmed after the meeting that it has launched a “one-time price increase”, mainly due to the tight global 8-inch wafer foundry capacity and the continuous price increase of silicon wafer materials.

UMC's current capacity utilization rate is approximately 95%, and its revenue for April and May all met expectations. The operation of the UMC was stable during the quarter. The company recorded NT$149.2 billion in revenue last year, a record high. It is expected that the annual growth rate of the global semiconductor market this year will be more than 10%. Although UMC is still in the phase of adjusting its physique and product line, this year's growth may be lower than the overall market, but it is still expected to have a certain degree of growth, and a new record high.

It is understood that with the strong demand for chips such as driver chips, fingerprint identification, power management, MOSFETs, and microcontrollers (MCUs), a large number of 8-inch wafer foundry capacity needs are being demanded. However, the current global fabs are runs for 12-inch wafers, the 8-inch plants are mainly for mature processes and no new plants have been added in recent years. However, the demand for chips such as driver chips that still use mature processes has been strong, resulting in the global 8-inch wafer production capacity fully occupied, showing a supply exceeding demand condition.

Liu Qidong explained that there are two reasons for the price increase. First, the supply of silicon wafers, the most important upstream material for wafer foundry, is tight and prices are increasing frequently. Although UMC has long-term supply contracts with suppliers, silicon wafers are available for supply. The goods were innocent, but the increase in the price of silicon wafers also resulted in higher UMC costs. Secondly, since this year, other companies have increased the prices of 8-inch wafer foundry one after another, but UMC has not previously performed any action. As silicon wafer prices have risen steadily, UMC has recently formally adjusted prices to reflect market mechanism and cost fluctuations.

Liu Qidong does not want to disclose the price increase rate. The industry has estimated the cumulative rise of other companies since the beginning of this year, as well as the rising cost of space caused by the price increase of silicon wafers. It is estimated that UMC's increase may reach about 20%, compare with the past price increase which generally between 3% to 5%, this time seems to be the biggest increase in history.

In response to strong customer demand, Liu Qidong stated that UMC Taiwan's 8-inch factory has no space for further expansion, and will launch the 8-inch factory expansion plan in mainland China. The monthly production capacity is expected to increase from the current 60,000 to 70,000, an increase of over 15 %, completed in the second quarter of next year.

UMC emphasized that in recent years, the global demand for 8-inch wafer foundry market has been hot, and this expansion is only taking into account the supply and demand conditions in the medium and long-term markets.

All Comments (0)