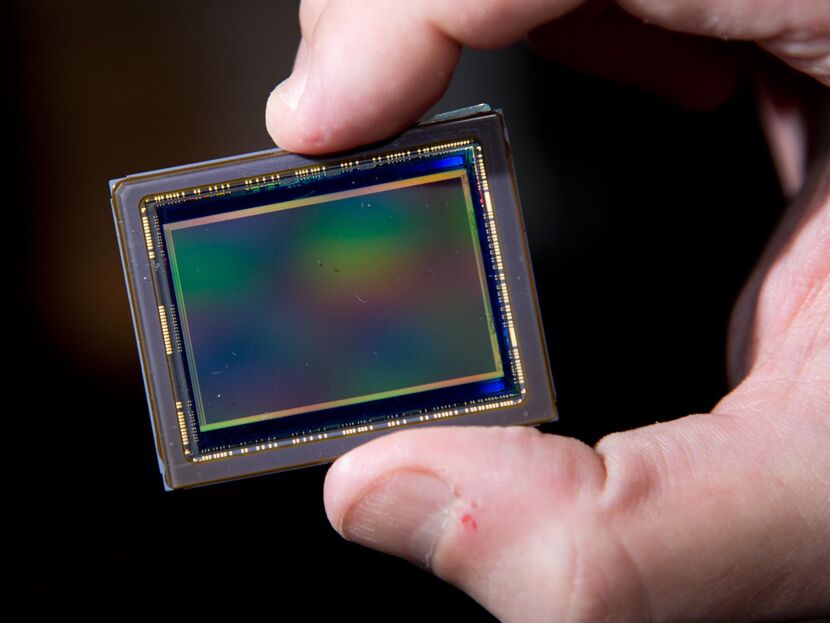

April 3, 2024 /SemiMedia/ -- Sony Group recently announced that a new semiconductor factory in Thailand began operations in February to increase the production of automotive image sensors. The new factory will mainly produce image sensors for advanced driver assistance systems that detect pedestrians and obstacles.

According to earlier reports, Sony invested approximately 10 billion yen (US$66 million) to expand a new factory at its existing factory in Pathum Thani Province, central Thailand.

Sony's new factory has expanded its production scale by 70%. After the expansion, the company expects to create 2,000 new jobs by 2026, 20% of which will be engineers. In addition, Sony Group has reserved space in the new factory for future expansion to meet the increase in demand.

"We expect mid- to long-term growth and will produce highly competitive products such as vehicle image sensors," said Terushi Shimizu, president of Sony's Semiconductor Solutions Group.

The new factory will handle the back-end processing of image sensors. After front-end processing in Japan to form circuits on the wafers, they are exported to factories in Thailand for cutting and packaging into finished products.

Advances in autonomous driving are expected to increase demand for Sony Group's high-performance image sensors. The company aims to achieve a 39% market share in this field by fiscal 2025, an increase of 14% from the current level.

In addition, the new factory will produce a new type of laser diode for use in high-capacity hard disk drives, a technology that has attracted attention for use in data centers. The diodes will be supplied to US data storage company Seagate Technology.

All Comments (0)