Nexperia has announced a partnership with renowned automotive engineering consulting company, Ricardo, to produce a technology demonstrator for an EV inverter based on gallium nitride (GaN) technology.

GaN is the preferred switch for these applications as GaN FETs lead to systems with greater efficiencies at lower costs with improved thermal performance and simpler switching topologies. In automotive terms this means that the vehicle has a greater range – the major concern for anyone looking to buy an electric vehicle. GaN is now on the brink of replacing silicon based IGBTs and SiC as the preferred technology for the traction inverters used in plug-in hybrids or full battery electric cars.

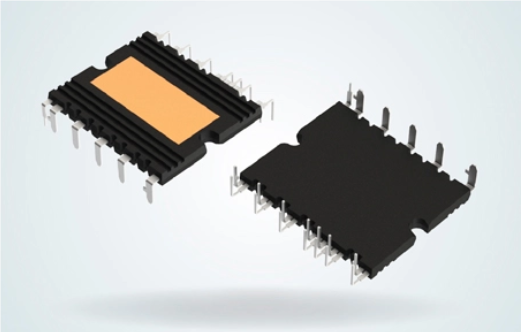

Nexperia announced a range of AEC-Q101-approved GaN devices last year, providing automotive designers with an ever-widening portfolio of proven, reliable devices in this high-efficiency technology, providing the power density required for electrification of the powertrain. Ricardo is very well regarded in the automotive industry, the Global engineering innovation company designs and consults on concepts within the automotive industry, including the manufacture of prototypes and demos, and boast collaborations with high-profile leading brands such as McLaren and Bugatti. Ricardo was the perfect partner for Nexperia for this project.

Michael LeGoff, General Manager GaN, Nexperia: “By designing our GaN devices into an inverter and trialling them through Ricardo, we will be able to better understand how a vehicle can be driven safely and reliably. We are developing a real solution that I think a lot of automotive designers will be interested in having a look at and will find extremely advantageous.”

Adrian Greaney, Director Technology & Products, Ricardo: “Semiconductor technology is key to the efficiency of the inverter system and the role that it plays in the performance and efficiency of an electrified vehicle. By delivering significant benefits in terms of the switching speed and efficiency, gallium nitride is a real enabling technology. As well as leading to increased range, it allows us to reduce the package size and weight of the inverter, which provides greater powertrain design flexibility as well as contributing to vehicle mass reduction. There are also many associated benefits that when we look at the design from a system level, and Ricardo is therefore pleased to be collaborating with Nexperia on GaN devices.”

All Comments (0)